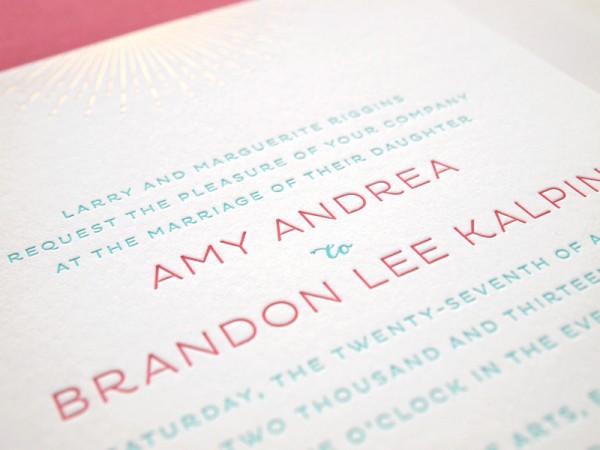

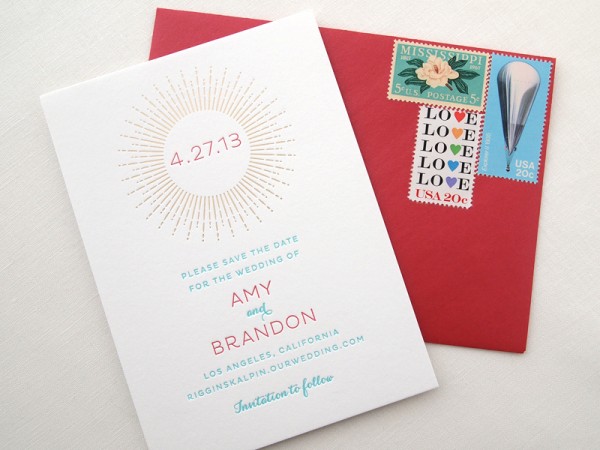

Happy Monday everyone! I’m thrilled to be starting the week with a gorgeous set of invitations with architecture-inspired details from Lisa at Missive! Lisa incorporated a beautiful gold foil starburst detail inspired by chandeliers at the wedding venue along with modern sans serif and script fonts. I love the combination of the gold foil with the bright red and aqua color palette. The entire suite is so pretty!

From Lisa: Amy and Brandon’s wedding suite was inspired by interior architectural details at their wedding venue. The chandeliers inside the venue had an interesting starlike pattern that Amy wanted to incorporate into her invitations, so I designed a starburst element which was carried through from her save the date to wedding invitations to thank you notes, where it appears as their new monogram.

Once I learned more about Amy’s vision for her venue decor — from a huge curtain of red and aqua fringe streamers and gold dot garland to jars filled with glowing candlelight, it was clear that her wedding invitation suite needed a glamorous feel. The invitations were letterpress printed in Amy’s bold wedding colors, a rich red and vivid aqua blue, complemented by the shiny gold starbursts.

Modern sans-serif typefaces were paired with an exquisite, flourished script for all of the pieces in this suite. We upped the glam factor with envelopes in bright punchy colors, which were also foil stamped with the couples’ return address. This suite was all about sparkle and shine and I loved that the bride did not shy away from bold color and gleaming gold details!

In celebration of the new Missive website and online shop, Lisa has generously offered Oh So Beautiful Paper readers an exclusive 20% discount for the month of June, including personalized letterpress stationery and calling cards! Just use promo code OSBP20 at checkout – thanks so much Lisa!

Design + Letterpress Printing: Missive

Foil Stamping: Quality Letterpress

Check out the Designer Rolodex for more talÂented wedÂding inviÂtaÂtion designÂers and the real inviÂtaÂtions gallery for more wedding invitation ideas!

Photo Credits: Missive

Â

Â