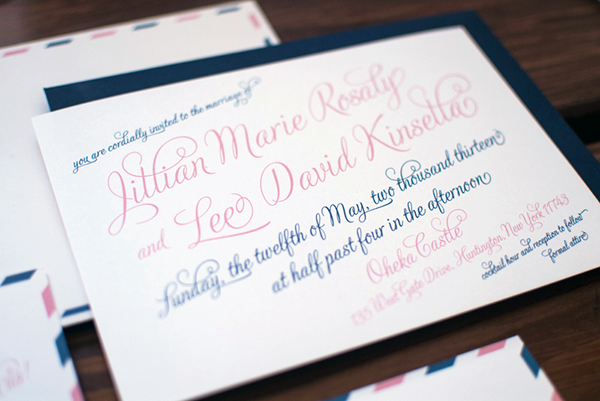

After many years as a long distance couple, Jillian and Lee worked with designer Christine Loo of Heritage + Joy to create a travel-inspired wedding invitation suite with airmail details. Christine also incorporated Jillian and Lee’s color palette of cream, soft pink, and navy blue and elegant script fonts to complement their castle (!!) wedding venue. So lovely!

From Christine: Jillian and Lee were married this past May at the beautiful Oheka Castle in Long Island, New York. They decided to go with a travel theme to reflect the nature of their long distance relationship. She is originally from New York, he from the United Kingdom. Over the years, they had travelled many miles to see each other and spend time together, from London to New York to Paris. Lee even proposed on a special trip to St. Lucia!

Jillian and Lee chose a beautiful color palette for their castle wedding — soft pinks and creams for their flowers, and long navy dresses for the bridesmaids. We worked together to design a wedding invitation suite that was modern, soft, with just a hint of vintage flair to reflect handwritten letters.

I created different variations of passport stamps that we incorporated into the suite that reflected some of the different locations they had travelled to. The suite was printed on soft white paper and inserted into navy inner envelopes before going into outer envelopes, giving them just the right elegant touch.

Thanks Christine!

Check out the Designer Rolodex for more talÂented wedÂding inviÂtaÂtion designÂers and the real inviÂtaÂtions gallery for more wedding invitation ideas!

Photo Credits: Heritage + Joy

Â

Â

Â

Â