I hope you’re ready for some amazing calligraphy inspiration! This month’s calligrapher of note is the lovely Korie Lynn Herold of  The Weekend Type. Not only is she doing great work behind the camera as a talented wedding photographer, she’s providing beautiful work for the camera as a calligrapher. Her portfolio is a stunner – filled with hand-lettered goodies for you to feast your eyes on. – Julie

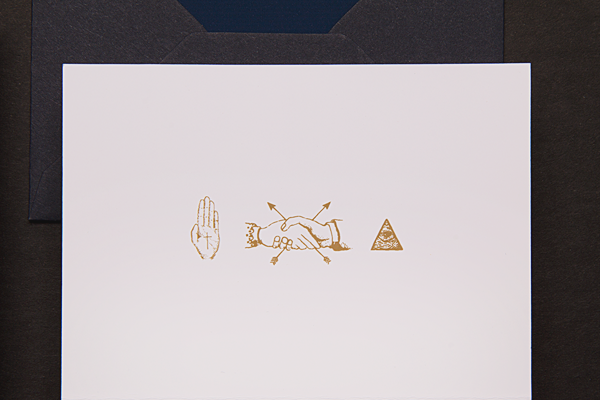

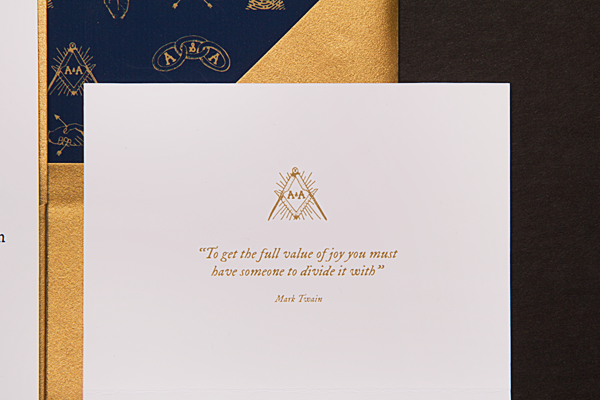

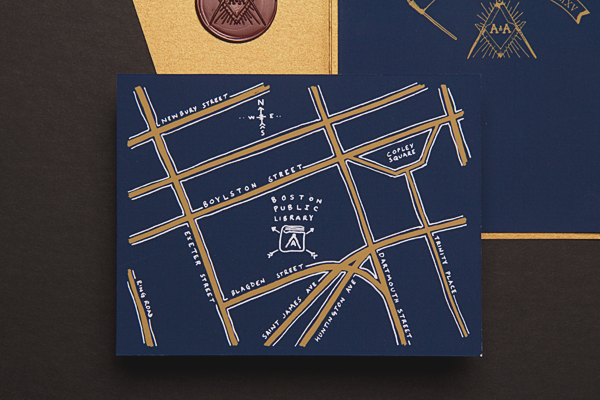

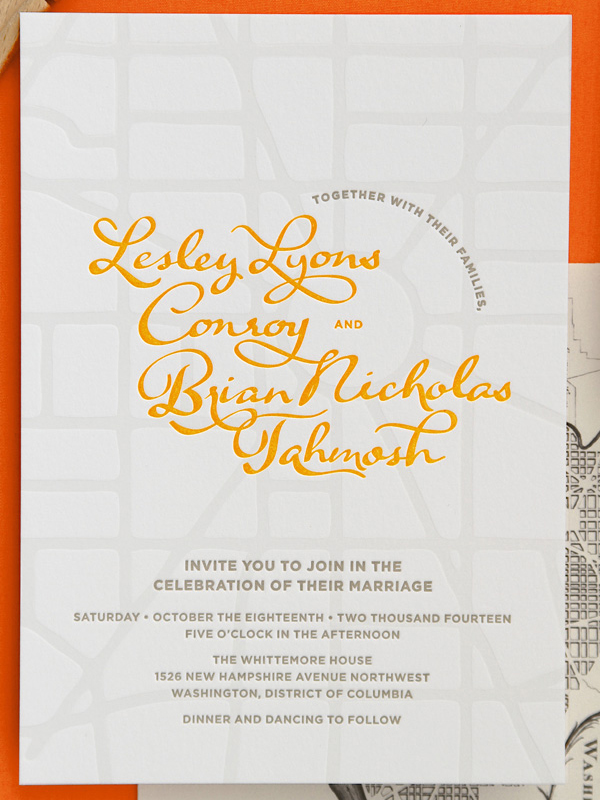

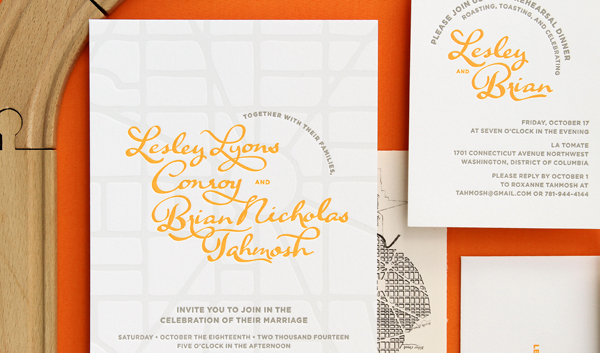

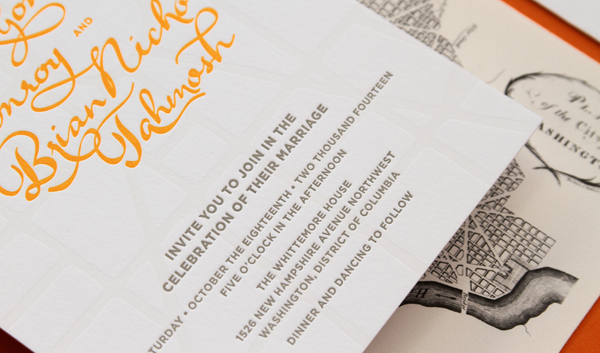

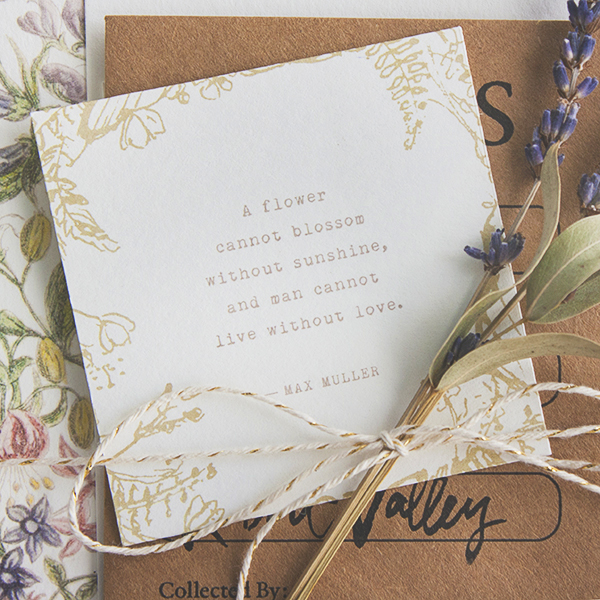

Simple light and wispy threads of ink make these wedding invitations utterly romantic. A gorgeous option for those seeking strong yet silent stationery.

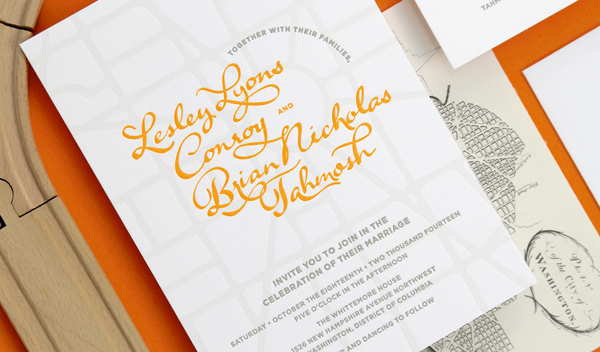

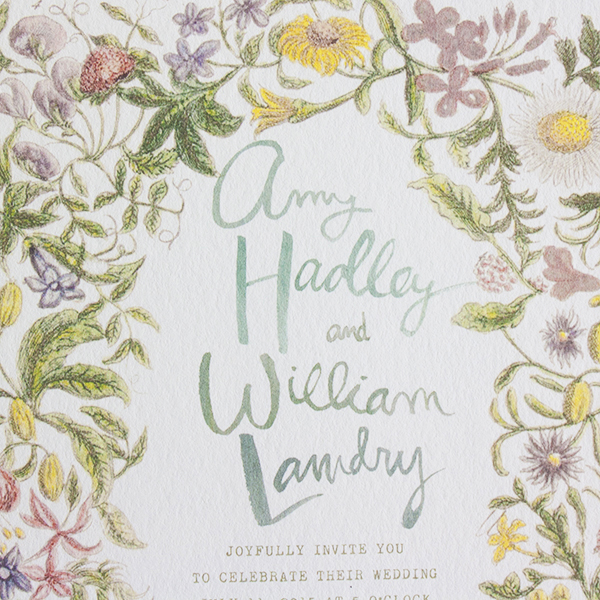

This message in a bottle invitation definitely works much better with lovely calligraphy rather than something overly kitsch to play on the theme.

To see more of Korie’s calligraphy, be sure to check out her blog and Instagram!

Photos via:Â Korie Lynn Herold