Known for playful hand lettering and vibrant colors, it’s hard to believe that The Paper Cub Co. is only a couple years old! Owner and designer Shannon Kennedy started out in apparel design before transitioning to work freelance and, ultimately, starting The Paper Cub Co. in 2013. Following her desire to be her own boss, Shannon has found ways to make her business scalable, primarily by outsourcing printing and focusing on designing – working smarter, not harder. Read the rest of her business story below! –Megan

Prior to starting The Paper Cub Co., I had a collection of art prints and accessories for kids called sass&peril. Before that, I was an in-house Graphic Designer for a juniors apparel brand out in California. After working in the corporate design world for 4.5 years and experiencing the highs and lows associated with that, I began to feel the tides start to shift. I felt I wasn’t fully able to satisfy my creativity at the workplace, so I began pulling my own art prints at night and on the weekends. I realized I could actually create my own products to sell online and essentially become my own boss, which is what I had always wanted all along. Plus, paper was an exciting new medium for me after all those years in fashion!

I went freelance for a number of years, which allowed me to pour more into my own creative endeavors but still have some steady work to rely on as I built things up. In the Spring of 2013, I showed a small collection of greeting cards along with my kid’s stuff at the National Stationery Show and the stationery side of the business really took off from there. A few months later I decided to consolidate the two brands into one and focus more on paper goods under The Paper Cub Co.

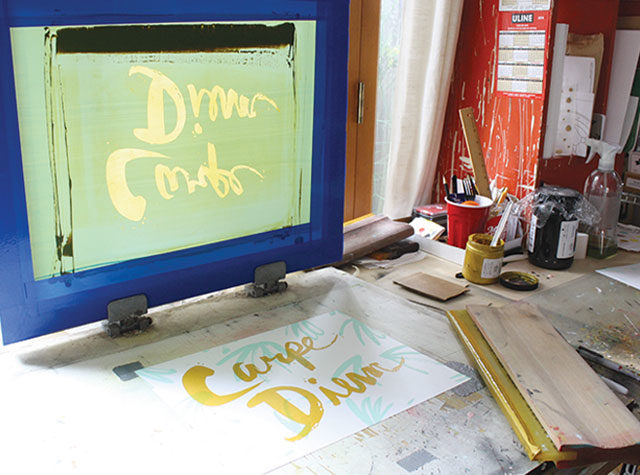

Each design originates in my sketchbook. If I am feeling the idea, I will work out the design elements using brush and ink and/or various pens on paper. Sometimes ideas are taken straight to the computer if it is a simple type-driven composition, but the majority of the designs in our collection have a hand-drawn element to them. My sketched elements get scanned into Photoshop where they are cleaned up and made into .tiff files to be used for mocking up designs in Illustrator. I finalize all designs using Illustrator as it is perfect for screen printing because it produces vector-based elements and nice solid shapes.

Photo by By The Robinsons

Photo by By The Robinsons

Once designs are dialed in and colors are determined, I will pair them up with other designs of similar colors so that they can be “ganged up†on a sheet for printing. What this means is that I can print up to eight different designs as long as they share the same colors on a single sheet of paper. (No more printing one card at a time, how’s that for efficiency?)

If I am doing the job myself, I have films printed for each color layer (called separations) and then I coat and burn screens using the films and photosensitive emulsion. This creates a “stencil†of the design in the screen for which ink is pulled through with a squeegee to create a print. It is quite a process, but so fun and rewarding!

I used to screen print each one of our greeting cards, one at a time, by hand. It was a great way to utilize my skills while building the brand and creating initial inventory. I could kind of see how designs performed and create products on demand. When I entered the wholesale market and volume became an issue, I decided to get some help.

Our friends over at Mama’s Sauce are amazing printers so it was a no-brainer to employ their screen printing services for our cards as they can fit many more designs per sheet. Since all they do is printing, they have access to bigger and better equipment and offer more professional-looking finishing services. Not to mention they are local and we can pop in for press checks or just to say hi! It’s a win-win. I still screen print our art prints and special projects, but the best decision I made was partnering with them for card printing as it leaves me with more time to design and market our brand.

Photo by By The Robinsons

Photo by By The Robinsons

Switching to outsourcing has taught me how to work smarter and to really get the most bang for my buck out of every business decision I make. You know, pay attention to margins and all that fun stuff. I was spending so much of my own time and valuable billable design hours being the manufacturer when it was more efficient for me to be the designer.

I now have the ability to take on more freelance and commissioned work, which pays more per hour than me printing my own stuff, and it has allowed me to grow more creatively. I’m truly glad that I did it all in the beginning because investing in inventory can be a calculated risk, but partnering with the right people to help you grow your business is equally as important. Just because you can do something doesn’t mean you always should!

Photo by By The Robinsons

All photos by The Paper Cub Co. except where noted.

Interested in participating in the Behind the Stationery column? Reach out to Megan at megan[at]ohsobeautifulpaper.com for more details.

Shannon’s story has resonated deeply with me as I am in the same transitional period. I do hope to find my happy medium as she has done. And I also hope to produce such wonderful designs. Thanks for a lovely read. 🙂

That last sentence is exactly what I needed to hear right now. Thanks for sharing your story Shannon and cheers to much continued success!

Yes!

Loved this story, very inspiring and wonderful to read!