Remember the blog field trip that I took a couple of weeks ago?  Well, I’m finally ready to share photos from the trip!  A couple months ago, Crane & Co. stationery invited me to visit and tour their facilities up in western Massachusetts (near the Berkshire mountains).  In case you’re not familiar with Crane’s history, the company was founded in 1801 and has been producing cotton paper and stationery ever since – making Crane one of the oldest companies in the United States!

We started the tour off with lunch and a discussion at the Crane Model Farm in Dalton, Massachusetts. Â The Model Farm was originally the home of founder Zenas Crane and is now used for social and business functions.

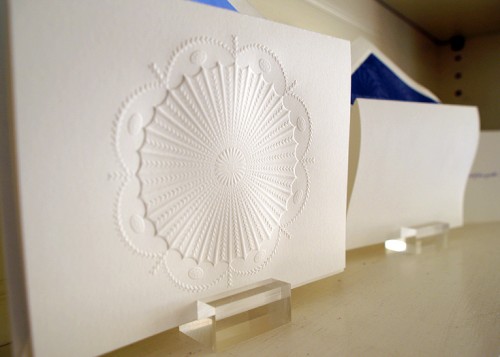

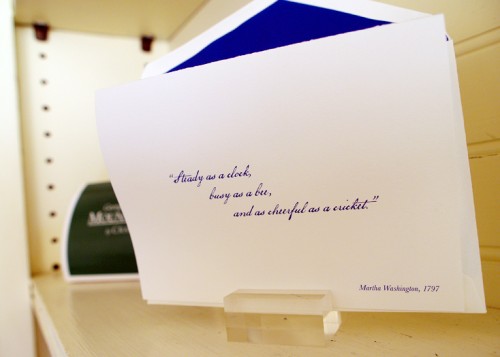

Of course, a Crane facility wouldn’t be complete without a display of beautiful stationery…

Crane is known for its engraved stationery and invitations (I was particularly excited to see the engraving process in person during this visit), but also offers letterpress, flat printing, and thermography. Â Fun fact: Crane also makes the currency paper for the United States and several other countries. Â More on that a bit later on…

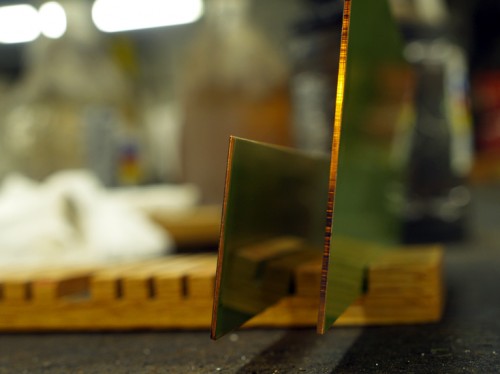

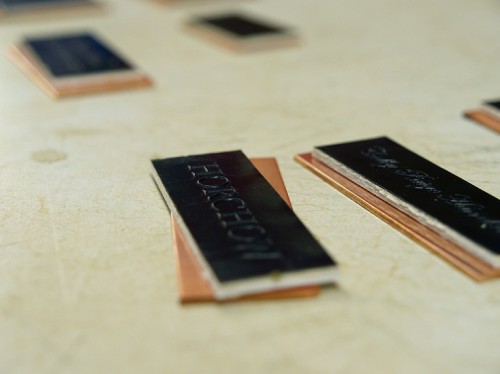

Later, we moved over to the Crane Personalized Design Services center, where all custom orders – from wedding invitations to business cards to personalized holiday and greeting cards – are processed and printed.  Now we get to some of the action shots!  First up, the pre-production process – where the custom text is etched onto a copper plate in preparation for printing.

{the red solution is a blocking material that prevents the chemicals from etching anything other than the actual text}

After the blocking material is applied, the plates go into a separate room to go through the etching solution…

{printing can get very dirty – no matter how elegant the result!}

{once the copper plate has spent enough time in the etching solution, it gets washed down to remove any residual chemicals}

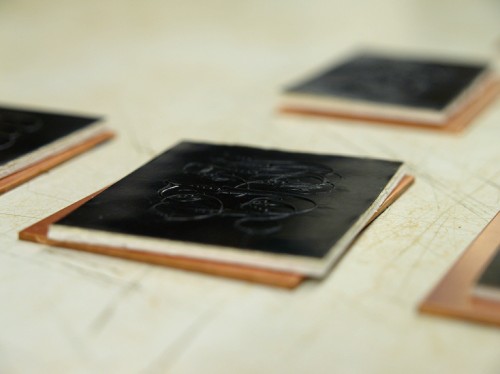

{the photo above shows what the plate looks like after it comes out from the etching solution}

Crane tries to fit as much text onto each sheet of copper, often from multiple projects. Â Once the plate is fully etched, the copper sheet is cut down to the appropriate size for each individual project.

Up next, the Crane printing floor – with engraving and foil stamping in action!

{all photos by me}

*Disclaimer – Crane & Co. provided my accommodations during this visit; but this is not a sponsored post.  For more on my editorial policies, please click here.

This is kind of what I wish heaven looked like 🙂

What a fantastic opportunity. Can’t wait to see Part 2.

An amazing opportunity, I would love to have a tour! Such a beautiful building too

Wow, how fun to catch a bit of the history and behind-the-scenes work at such a great institution as Crane! Thank you for sharing.

Great to see this and glad you enjoyed the Model Farm.

I have to input that the Model Farm was built in 1898 by Frederick G. Crane who was the grandson of Zenas the founder.